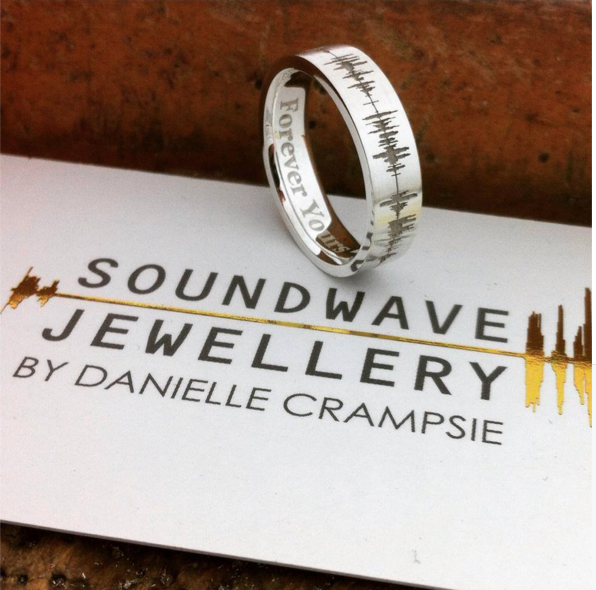

Oops! I made this ring a half size too small. Mistakes happen but it is important to know the proper way to fix them.

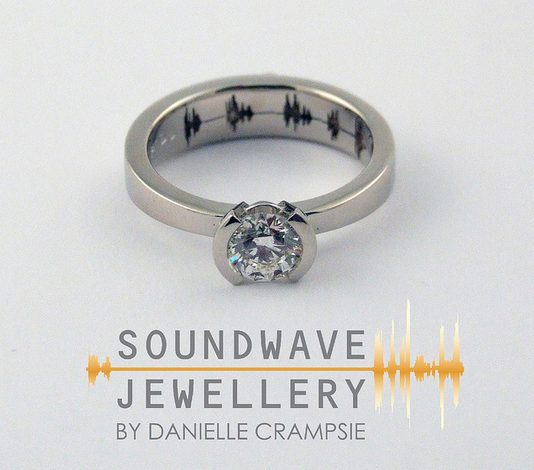

The are a few ways of sizing a ring. Some rings can be stretched by hammering them against a steel mandrel. This leaves hammer marks out the outside of the ring which need to be filed, sanded and re-polished. That technique is not an option here with this beautiful soundwave already engraved on the outside, hammering it would surely damage the design.

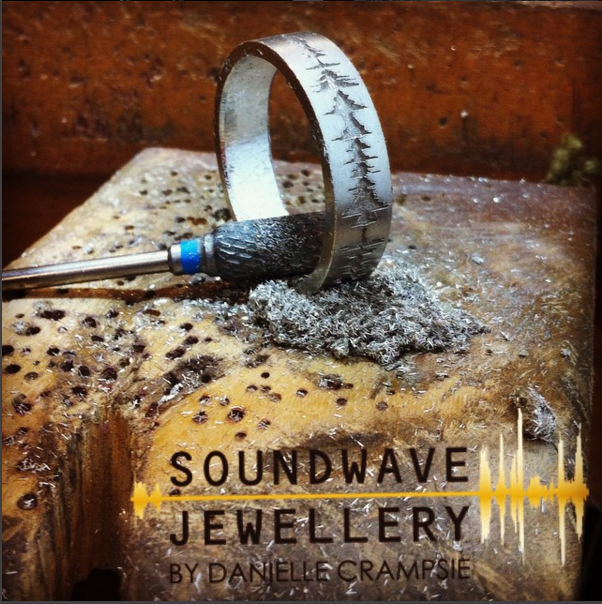

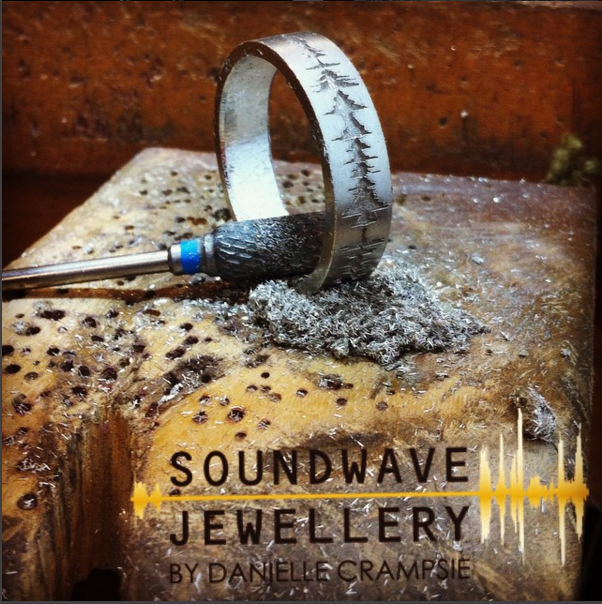

In order to achieve this sizing I needed to grind it out from the inside using my favourite titanium rotary file. It is quite aggressive and created that big pile of metal shavings! These shaving tend to get stuck in your hands like little splinters.

It sounds very luxurious to have splitters of gold in your hands but in reality the really hurt if don't pick them out with tweezers right away. Luckily goldsmiths always have tweezers around. They are used to pick up hot metal when soldering, position delicate design elements and sort through and examine stones. I usually use my prized stone tweezers for this job. These tweezer are only used for stones therefore they are sharp and most importantly clean.

As with all jewellery techniques it's important to be patient and go slow and steady. You want to make sure you are removing material evenly so the walls of the rings stay the same thickness all the way around. This requires a steady hand and a gentle touch.

Once the correct size is reached a hand file is used to smooth out the deep marks the rotary file has created. Then three or four grits of sandpaper are used to prepare the ring for polishing. Polishing involves two or three polishing compounds which leave a greasy film on the surface of the metal. In between polishing compounds it is important to clean your piece so you do not contaminated your polishing buffs. Cleaning is done using an ultrasonic cleaner, it actually uses soundwaves to remove the dirt and greasy from the ring.

When polishing is completed the ring is steamed cleaned with a machine which uses heat and pressure to create steam. This removes any residue from the surface of the ring and steams away water marks so the ring is ready for presentation!