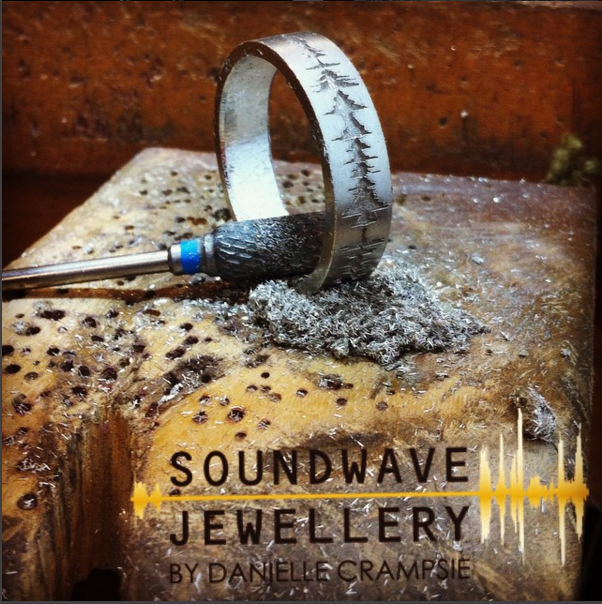

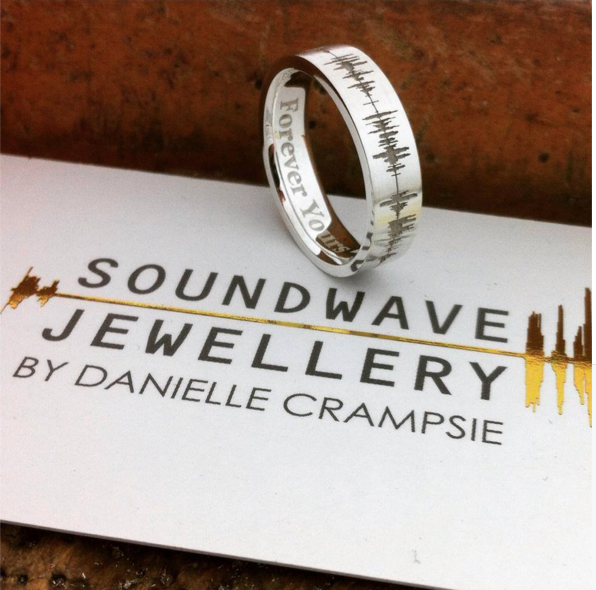

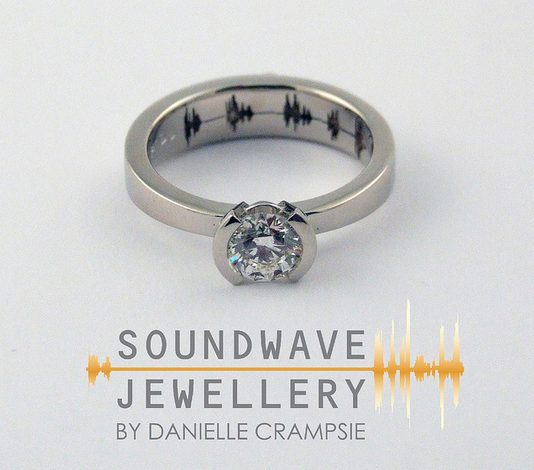

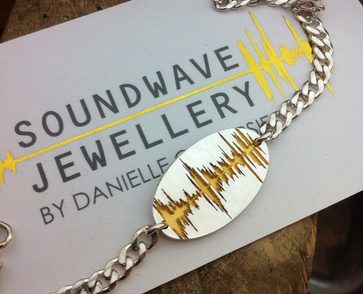

I've been working on the Soundwave Dog Tag for years. Only recently did the right technology come along to allow my vision to be fully realized. The challenge was always related to the depth of the etching. In order to colour the sound wave the etching has to be deep enough so when the entire piece is coated with the colour it is able to be removed off the surface without damaging the sound wave.

When I first started creating Soundwave Dog Tags I used a photo transfer process. The first sample created a really beautiful etching, not so deep but super sharp. The main issue was it is only achievable using nitric acid, not a pleasant material to have around. I moved onto a less harsh chemical, ferric nitrate. I found it hard to create the right mixture. If it was too weak the etching wouldn’t be deep enough, too strong and it would eat through the photoresist. I solved the problem by using the transfer paper to outline the design and then painted the outline of the sound wave carefully with a shellac. The photo paper was very hard to adhere to the surface of the metal and as you could imagine painting the entire outer edge of the sound wave was extremely time consuming.

I created the dog tag this way for a couple years, the time involved made these projects truly a labour of love. I had to find another way if I wanted to continue to create them. I briefly experimented using an industrial metal etching company. They could get the depth but could only etch material 0.8mm in thickness. I like the Dog Tag to be at least 1.1mm in thickness, this is not negotiable. I tried some samples using Cad/Cam technology and lost wax casting but the cost of the process was prohibiting. I was looking to make the Dog Tags an affordable gift item. Something special for a life’s event that doesn’t involve a ring. Around this time laser technology was getting really hot and being introduced to the jewellery industry through laser welders. I started experimenting with laser engraving.

The laser engravers in the jewellery industry looked super clean but still couldn’t achieve the depth I wanted. Eventually I found a laser intended for more industrial uses that was able to get the job done. Our first sample was actually too deep and left the piece at risk of bending and snapping in half. After a couple more try we were able to find the right depth.

Creating the perfect Soundwave Dog Tag has taken years. With the introduction of new technology I was able to achieve the quality I wanted and offer an affordable price point to my clients. Quality is of upmost importance to me and something that can not be compromised. For me the greatest feeling is being able to proudly stand behind my work knowing that every step was taking to insure the jewellery I create lasts lifetimes.

Record.Create.Express.